June 18th, 2024

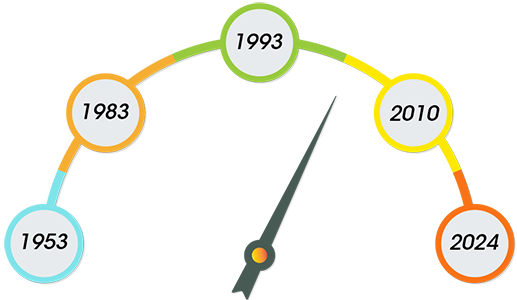

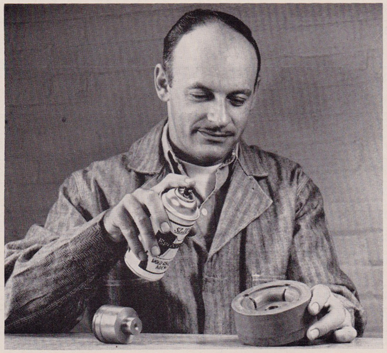

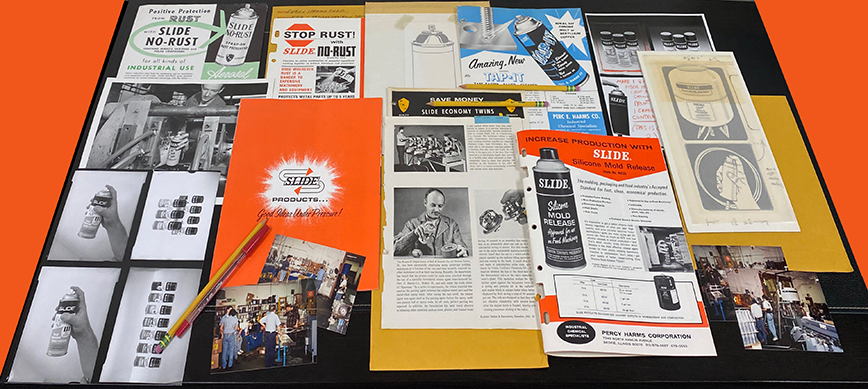

1953 – Percy Harms, who had been selling tool steel to molders and mold makers for several years, is asked by these customers for a mold lubricant to keep the plastic parts from sticking to the steel molds. Percy worked with his cousin, Howard Klemm, to develop the first four aerosol products offered by the company. This minimal product line included a silicone-based mold release, a rust preventive, a tapping fluid, and a blue layout dye. The enterprise was incorporated under the name Perc. E. Harms Corporation (he was worried people would refer to it as “Perky Harms” if he used his actual name “Percy”). In its initial phase the business was run from a garage at the family home located on George Street in Skokie, IL.

1959 – Percy finally succumbed and renamed the firm Percy Harms Corporation. During this time, the company was still not making its own products. Percy’s wife, Edna, grew increasingly tired of product being stored in the family garage and insisted that they find alternative warehouse space. Apparently, Edna was the one who ran the family. Percy agreed, and their whole business was moved to a small, rented warehouse.

1963 – Percy’s two sons, Jim and Henry, joined the company to facilitate growth, with both focusing on sales. An outside partner, Jan van der Graff, also became part of the organization. Jan was a chemical engineer by training, and he focused on product development.

1976 – As the business continued to grow, the decision was made to move to a larger space and to install its own aerosol filling equipment. The operation relocated to a former pudding factory in Wheeling IL. While Percy and Jim continued to focus on sales, Henry was tasked with installing the “new” aerosol filling line. However, nothing about the production line was new. The outside storage tanks were all used, the can labeler was converted from an old baby food jar labeler, and the filling equipment was all second hand. It took 18 months to get installed and functional, but the Percy Harms Corporation was finally able to manufacture its own products.

1983 – The company quickly outgrew their 4,000 square foot facility. Luckily, there was enough property to expand the existing building footprint. Another 6,000 square feet of warehouse capacity was added to the Wheeling location.

1992 – Percy Harms passed away at the age of 91. His two sons and partner, Jan, now owned the firm and were committed to expand Slide’s brand.

1993 – The original name, Percy Harms Corp., was officially changed to recognize our popular brand name Slide. We’ve been Slide Products since that time. Slide subsequently eliminated all HFC and CFC ingredients from the product line, thus offering the industry’s first line that complied with the Montreal Protocol.

1994 – A new crop of next generation younger team members enters Slide Products. These personnel are now Slide’s office manager, general manager, senior sales staff and company President.

1996 – The property next door became available for purchase. Slide quickly grabbed at the opportunity and snapped up the additional 12,000 square feet. The new warehouse housed all finished product, while the original building contained offices, production and raw material storage.

2000s – 2010s – Slide Products continues to grow with expanded distribution in Canada, Mexico, Europe, and Asia. The ability for contract packaging/private label segment increases.

2010 – Following his passing, Jim Harms’ daughters, Julie Harms-Muth and Jill Harms take over ownership of Slide Products, continuing a 70-year tradition of family proprietorship.

2012 – Slide’s first satellite warehouse is launched in California. All chlorinated chemicals are eliminated from its offerings, making Slide the first supplier in the plastics industry to take this step, further safeguarding product users’ safety and health.

2015 – Slide’s entire production line is replaced with new and faster equipment.

2016 – Slide’s second satellite warehouse in Georgia is opened.

2020s – Slide Products continues to flourish, adding more space and cutting-edge proficiencies. Recently completed or upcoming advancements include installation of a new storage tank, remodeling of the office area and enlargement of the Illinois warehouse. This is undertaken with the goal of being able to better support operations and customers.

When it comes down to ongoing progress, Slide is first and foremost grateful for being surrounded by a wealth of exceptional people – our internal team, customers, partners, distributors – none of this is would be possible without the consistent efforts, knowledge and dedication from everyone involved.