October 8th, 2024

The Origins of It All

In 1962, Tike Miller was searching for a replacement piece for his nativity set when he accidentally ended up developing a landmark vending machine that became a fixture in museums, zoos and various attractions across the United States. Children could peer into the device through a small window and watch as injection molding magic transformed molten plastic into an exciting handheld souvenir in seconds!

The distinctive smell of that hot plastic left a lasting impact, making the whole experience unforgettable. The Mold-A-Rama became an outstanding introduction to the world of manufacturing for many kids, where inserting a quarter was exchanged for a mini plastic toy and an impressive show.

Injection Molding Magic in Action

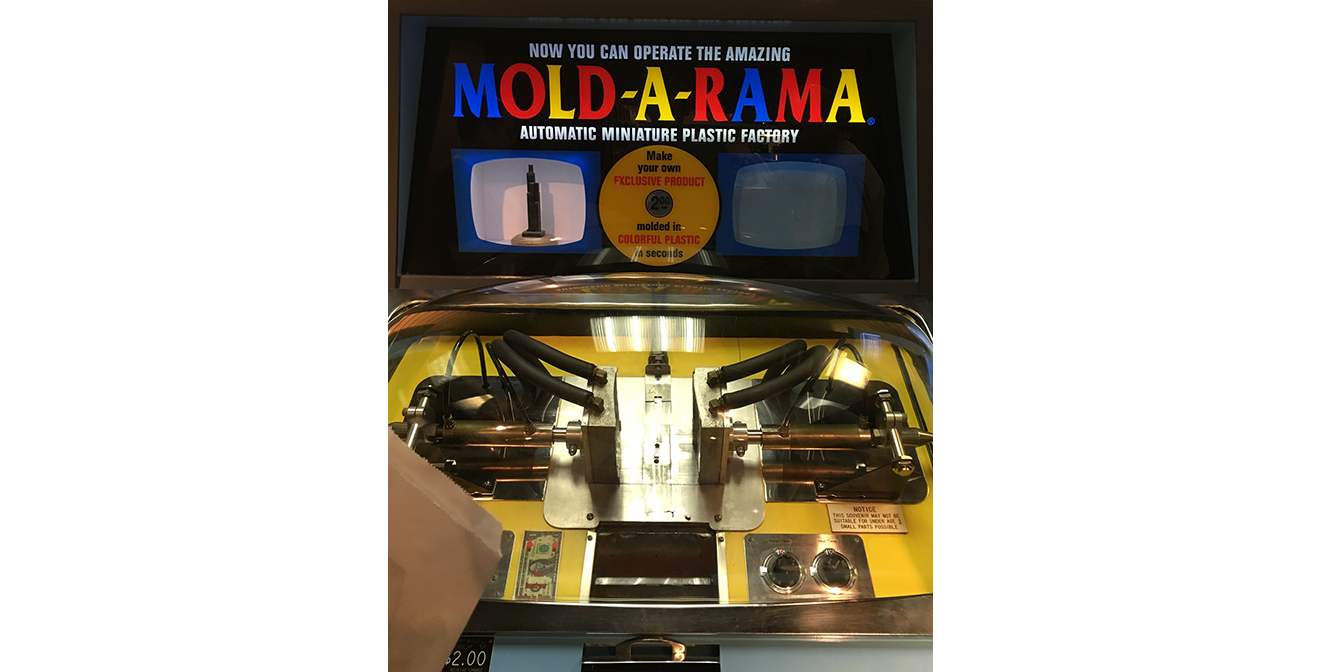

The Mold-A-Rama utilizes injection blow-molding to quickly produce figures while customers get to watch the process unfold before their eyes. Like a modern day 3-D printer, it generates plastic trinkets almost on demand, but instead of using computerized controls, it relies on mechanical gears. The machine uses a plastic composite called polyethylene, which is loaded into it in the form of colorant pellets. These components are subsequently melted at high temperatures ranging from 180° to 250°F and stored in a tank under the molds. This liquifying process is facilitated by steam passing through the coils in the holding tank.

Every product mold consists of an interchangeable cavity that is a reverse impression of the final piece. Using hydraulics, two aluminum plates press together from opposite sides to form a complete seal. Small holes at the bottom of these plates let air circulate and minimize heat when necessary. The hollow design of each cast accommodates coolant – such as water or antifreeze – which helps regulate the temperature throughout the whole progression.

When molten polymer runs within spaces between molds, each half is injected with pigmented liquid by an automated pump to sculpt the item. Once filled, compressed air is blown around to cool hot surfaces and solidify the plastic. In addition, cold water infiltrates the mold block, reducing the temperature of shaped figures. Any uncooled liquid drains down a hole to produce an empty center. Finally, the two molds separate and a rod pushes the finished sculpture into a dispenser.

Each Mold-A-Rama machine features its own personalized, unique design and color. If an owner opts to change colors, this transition can take some time, often resulting in intermediate hues. For instance, transforming a dinosaur figurine from red to yellow might yield orange dinos, which collectors may find desirable.

The Impact

While contemporary manufacturing methods deliver remarkable complexity, the Mold-A-Rama provides an unparalleled opportunity to encounter a charmingly simple example of injection molding. There are only a few companies still operating these iconic relics, leaving the availability of Mold-A-Rama trinkets uncertain.

Evolutions in 3D scanning and printing could mean the nostalgic souvenirs will be more accessible for home production. However, nothing can replicate the unique experience of seeing those novel vending machines convert raw materials into finished “treasures” right before your eyes.

More Interesting Information About Mold-A-Rama

Maintaining Mold-A-Rama: Chicago’s Very Own Souvenir Machine (video)