April 8th, 2025

Among the many iconic toys, one of the most beloved across the globe are LEGOs. These simple blocks have brought immeasurable fun and creativity to many generations, enabling people of all ages to build virtually anything. The brand has held a high-quality standard for years, manufacturing extremely precise pieces, making constructing both satisfying and rewarding. Let’s look at how these magical bricks have evolved into such a symbolic brand around the world.

The Origin

The visionary behind the big idea was Ole Kirk Christiansen, a carpenter from Denmark who began his manufacturing journey making stepladders, ironing boards, and stools in a small woodworking factory. The Great Depression forced many customers away. However, this downturn didn’t stop Christiansen from coming up with a concept to create miniature replicas and thus marked the start of his toy legacy.

Before these pivotal blocks became what we know of today as LEGOs, Christiansen had to come up with a name for the growing business. He ended up picking out “LEGO” after the Danish phrase “leg godt” meaning “play well”. The word ironically also means "I put together" in Latin.

Influence

Meanwhile, in England, toymaker Hilary Fisher Page was producing self-locking building bricks. He sold his toys under the brand Bri-Plax and marketed them as “Kiddicraft Self-Locking Building Bricks”.

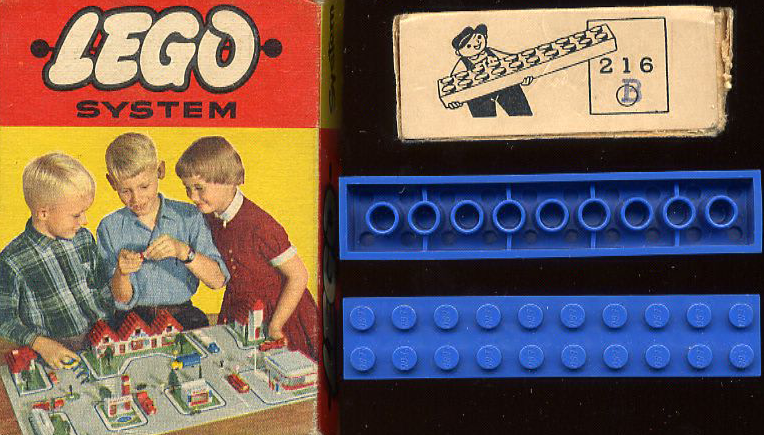

Post-war, plastic products were rising in popularity, which prompted Ole to invest in a new plastic injection molding machine. Inspired by the Kiddicraft blocks, Christiansen created a version of his own in 1949 – the Automatic Binding Brick – LEGO’s first ever official plastic molded interlocking pieces.

The “Ole” Fashion Way

The key differentiating factor in the way Ole Kirk Christiansen approached his design was a commitment to making all pieces compatible, allowing for unlimited possibilities.

While both LEGO and Kiddicraft utilized a self-locking design, LEGO's breakthroughwas certifying that every individual block could be interchanged with any other piece, creating endless combinations for constructive play. The quality of polymer found in LEGO bricks also gave them an impressive edge over any competitors. This standardization and precision became one of LEGO's defining characteristics and guaranteed that children could always add to their collection without worrying about fit.

First Official LEGO Set

After a decade of experimenting, Ole’s son, Godtfred, developed the “System in Play”, a model where every part would connect with each other. The breakthrough, introduced in 1958, was crucial to LEGO's success and laid the groundwork for the company's vast expansion in the years to come.

Godtfred remained determined to make his bricks even more dynamic, increasing the range of themes and pioneering different moving parts, subjects and colors. As LEGO grew in popularity, the first-ever LEGOLAND amusement park was built to showcase finished models. Today, there are more than 15 million visitors annually, highlighting this worldly cultural marvel.

The Future for LEGO Molding Machinery

Since acquiring their first injection molding machine in 1946, both technology and materials have radically evolved. By 1959, LEGO debuted its fully mechanized version, which significantly amplified manufacturing efficiency by letting workers manage two machines rather than just one. Today, one employee can operate 32 machines in a molding facility, producing 1,360 pieces per second. This progressive automation streamlines operations and helps to maintain LEGO’s massive output while upholding its superior standards.

The Global Impact of LEGO

More than just a toy, LEGOs have revolutionized the way children learn, especially in STEM, teaching kids about engineering, architecture and instilling problem-solving skills. This open-ended playing system has created a cultural movement by presenting a variety themes, offering fans an opportunity to engage in their favorite franchises. The bricks have contributed massively to education, imagination and visual arts, leaving us all with an unforgettable treasure.