November 5th, 2024

Each year, over 300 million tons of plastic waste are generated, with single-use throwaways accounting for half of this total. Plastic is the largest source of discard worldwide, often characterized by its short lifespan across industrial sectors, significantly contributing to landfills and our carbon footprint. Most conventional plastics originate from fossil fuels like petroleum and natural gas. Growing concerns about negative sustainable impact have prompted a shift toward utilizing more recyclable materials.

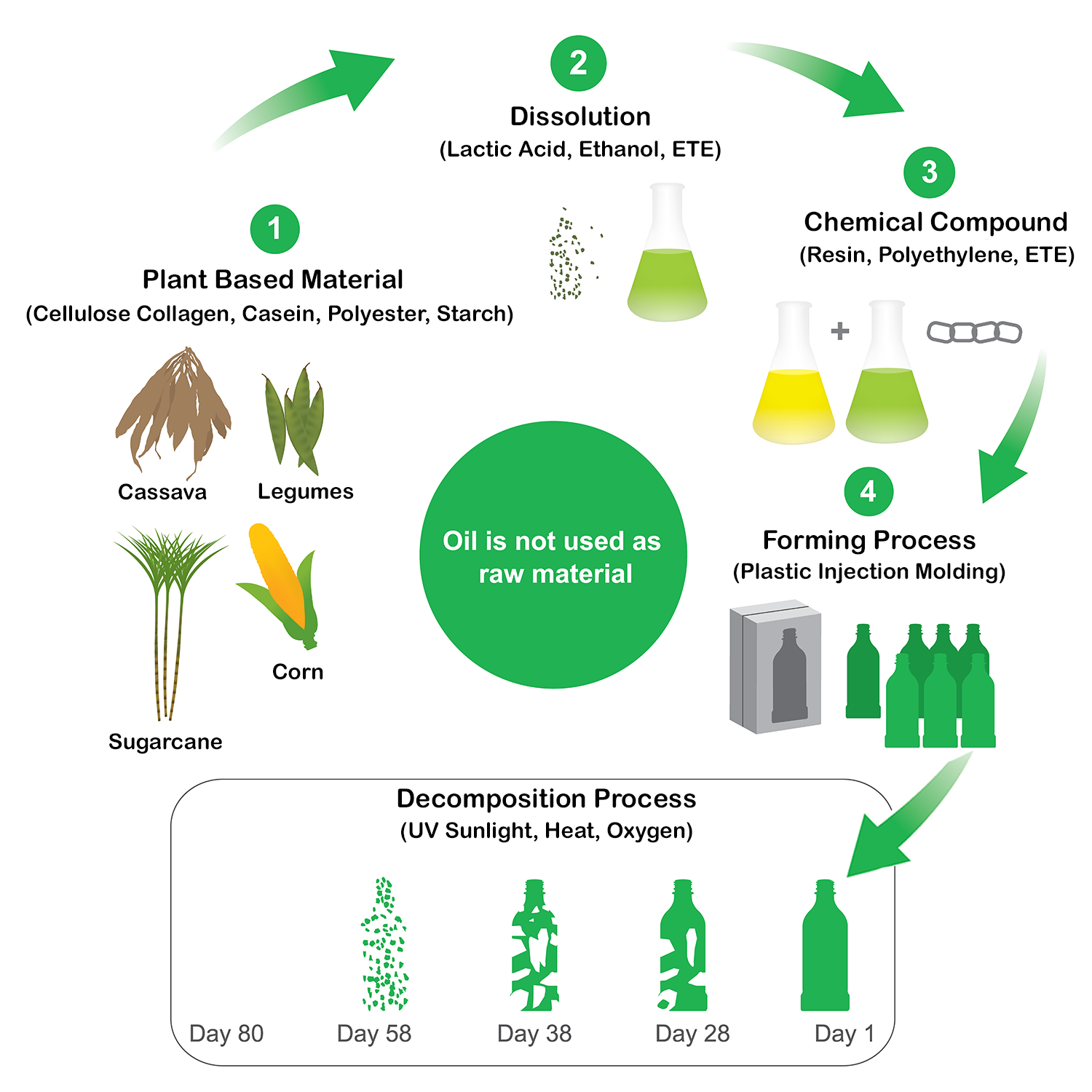

Bioplastics present a promising alternative to destructive polymers. They decompose quicker and support a stronger circular economy. Derived from renewable resources such as plant-based starches or sugars, these materials are less toxic and free from bisphenol A (BPA), a common hormone disruptor found in conventional plastics. Many of these resins are compostable, breaking down within months rather than years. This makes them ideal for disposable items like water bottles, cutlery and coffee pods. Incorporating bio-based products into existing production procedures can be done with minimal adjustments, optimizing results effectively.

The Composition of Bioplastics

Bio-derived polymers originate from a variety of substances and are developed and tested by chemical engineers. These composites can be utilized in consumable goods such as packaging, bags, 3D printing, automotive components and medical devices. The raw matter undergoes progressions like fermentation, extraction or other reactions to yield their final forms. Starch is one of the most prevalent sources, accounting for approximately half of the entire related market.

Two Key Categories:

- Type 1 – PLA (Polylactic Acid): PLA is primarily taken from viable resources such as cornstarch, cassava and sugarcane. It is eco-friendly, edible and reduces CO2 emissions. The molecular chains in PLA resemble those found in plastics made from fossil fuels, allowing it to mimic the properties of polyethylene, polypropylene and polystyrene. Notable attributes of PLA include excellent thermal and mechanical elements, as well as hydrophobic and gas-blocking capabilities, thanks to its nanomaterial composition.

- Type 2 – PHA (Polyhydroxyalkanoate): PHA is produced by genetically engineered organisms that synthesize plastic organically. These microbes employ nitrogen, phosphorus and oxygen to generate high levels of carbon. The chemical structure of these components resembles that of familiar polymers, yet PHA is biodegradable. This plastic is commonly used in injection molding for medical applications and single-use food packaging.

Growth in the Industry

Currently, PLA and PHA account for only about 1% of total created; however, such petroleum-based products have the capability to replace up to 65% of resulting output. The progression regarding sustainable manufacturing practices is driven by increasing consumer awareness and the significant unfavorable environmental impact of common plastics. Major brands like Ford, Heinz, Coca-Cola and Procter & Gamble are collaborating to explore plant-based options that minimize carbon emissions without compromising the food supply.

While this innovative approach provides a greener solution, biodegradation alone is insufficient to address the broader issue of pollution. Improvements in manufacturing techniques are being implemented across various industries to accelerate the adoption of ecologically sound alternatives. These collective efforts aim to yield wiser choices, reduce costs, foster innovation and ultimately lessen environmental harm. There is an expectation for the development of new materials with enhanced attributes, which will further broaden possible applications.

Bioplastics within Injection Molding

Bioplastics can be effectively integrated into injection molding by adjusting temperatures, pressure and designs to suit their specific characteristics. The formulation of PLAs and PHAs requires less energy than typical plastics and uses considerably fewer toxic additives. This transition helps decrease our reliance on non-renewable reserves like petroleum.

As technology continues to advance, improvements in production methods and quality control will unlock the full potential of these polymers. While research is ongoing, advantages of bioplastics represent a transformative change in the industry, to lead the way for more responsible practices.