February 3rd, 2022

2021 was a year of highs and lows for the plastics molding industry. Success in areas such as medical devices, consumer staples and food packaging came with challenges due to supply chain disruption and inflationary pressures on raw materials. Here at Slide, we celebrated the good this year and worked hard to find solutions to mitigate the bad.

Our 2021 industry update explores these volatile market conditions and how Slide Products was able to provide reliable and high-quality solutions. With a strong focus on saving our customers time and money, we were determined to make last year as smooth as possible. Here are some of the biggest plastic molding events of 2021.

High Demands

As life began to slowly return to normal so did consumer spending. Demands for everything from basic consumer goods to luxury products skyrocketed above pandemic lows. This caused plastics production to ramp up, leaving many suppliers without adequate resources. Slide was able to meet this challenge head-on by reducing cycle downtime with their vast array of products and expertise.

In particular, the injection molding market is heavily dependent on vehicle sales. While this industry also had a lot of ups and downs throughout 2021, overall sales increased by 9.1% creating a greater need for plastic parts. Both vehicle interiors and exteriors require injection molded pieces, plus a high level of expertise. Additionally, with more consumers buying secondhand cars, plastic parts were being excessively sought-after for refurbishment purposes industry wide.

A New “Normal”

As safety is still everyone’s number one priority, the pandemic has led to many new trends for which the plastics industry had to respond. The biggest of these is arguably individual food packaging. With the increasing popularity of convenience meals alongside safety concerns of pre-handled foods, you can now find almost anything in a packaged format. From restaurants to buffets, many traditional food serving methods now involve individually wrapped options. The global food packaging market is expected to reach over 478 billion USD by 2028, providing huge opportunities for the future of plastics processing.

The medical field in 2021 also greatly relied on plastic molding. With new covid vaccines rolling out while hospitals were at record capacities, plastic products were needed more than ever. Everything from components of medical devices and equipment to laboratory tools and testing instruments were in high demand. Slide’s products were utilized this year to safely produce these important medical components and subsequently aid in containing the pandemic.

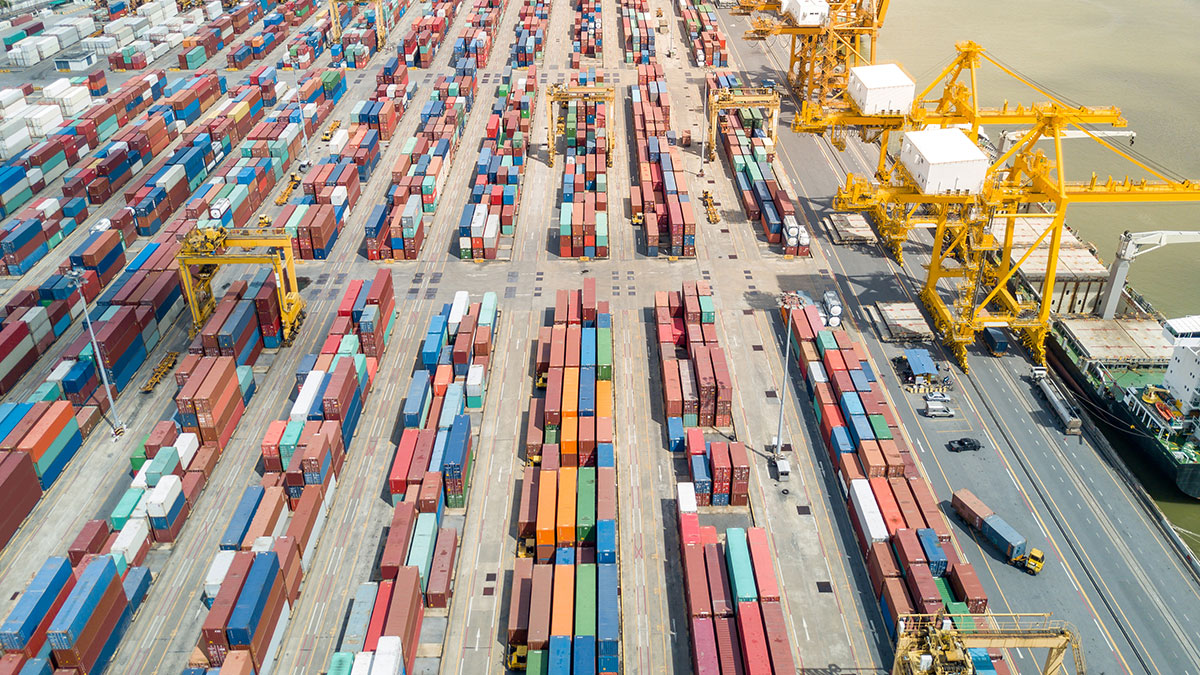

Supply Chain Bottleneck

Supply chain issues affected almost every industry this year. Often preventing supplies from getting from one place to another, this severely stunted progress while making everything more expensive. For the plastics industry in particular, it was vital to plan ahead and store excess materials. Keeping up with demand was a struggle while timelines were being considerably stretched.

Although prolonged shipping times and rising costs can’t be controlled, the plastic industry worked hard to combat these issues with short- and long-term solutions. While we have not fully rectified this imbalance between supply and demand, Slide continues to be proactive and encourages others to be the same. Working together, we can share positive results through mutual flexibility.

Rising Resin Costs

Resin availability issues were another problem in 2021. The lack of resources caused prices to increase from 30% to even 50% for some products. This was largely due to a combination of pandemic-related problems alongside supply chain and weather issues. As price jumps reduced molders’ operating margins, many aspects of the plastics industry were severely hurt.

While 2021 wasn’t the easiest year for any of us, the Slide team wants to thank you for your loyal support and patience as we got through it together. From our customers to our distributors, we are grateful for your continued understanding. We look forward to working with you another year, meeting any highs and lows the plastic molding industry brings our way. We are also optimistic to use what we’ve learned to improve throughout 2022.