The right mold release agent increases production capability and extends the life of your molds, with shortened cycle times that go straight to your bottom line. Material and application-specific formulations that prevent sticking and enable the speedy release of defect-free parts to drive greater productivity for injection molding or blow molding. Read More...

#400

Paintable Mold Release Agent

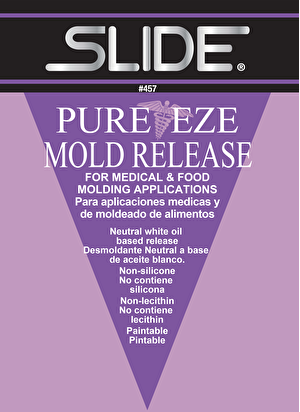

#457

Pure Eze Mold Release

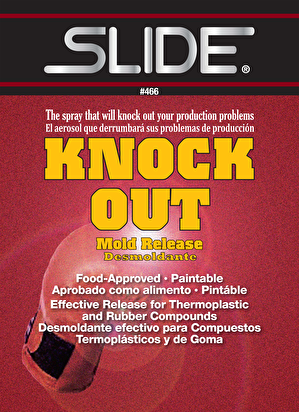

#466

Knock Out Mold Release

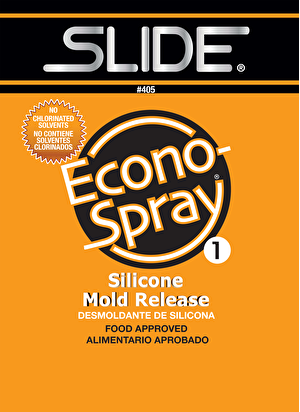

#405

Econo-Spray® 1 Mold Release

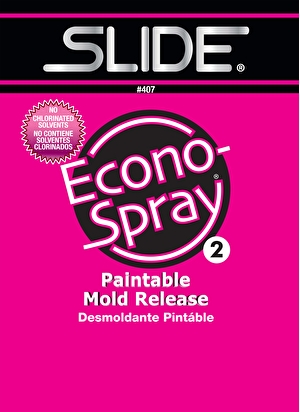

#407

Econo-Spray® 2 Mold Release

#458

Urethane Mold Release

#401

Silicone Mold Release

#411

DFL Dry Film Lube Mold Release

#410

Zinc Stearate Mold Release

#406

Epoxease Mold Release

#549

Heavy-Duty 10% Mold Release

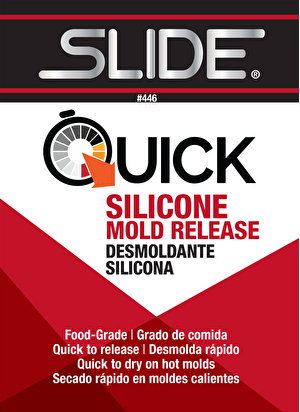

#446

Quick Silicone Mold Release

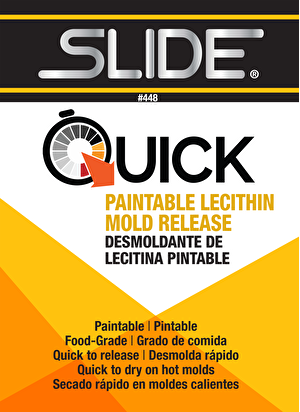

#448

Quick Lecithin Mold Release

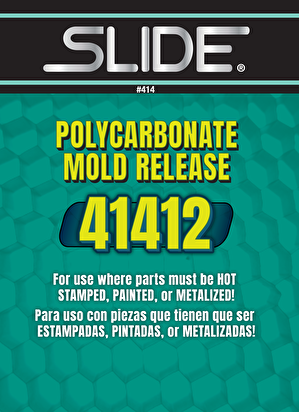

#414

Polycarbonate Mold Release

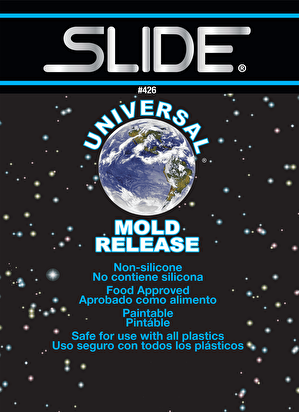

#426

Universal Mold Release

#454

Thermoset Mold Release

#435

LMR Lecithin Mold Release Concentrate

#441

Hi-Temp 1800 Mold Release

#417

DuraKote Mold Release for Thermosets

#529

DuraKote Variation Mold Release

Answers are just a click or call away!