Mold Release, Cleaner & Rust Preventive White Papers

The right steps to ensure maximum productivity without marking parts

Lubricating ejector pins is essential to preserve the life of an injection molding tool. The wrong procedure or the wrong lubricant can cause problems and even lead to tool damage . Problems, such as bleeding out onto the tool surface, can cause defective plastic parts. Thermal and viscosity breakdown can cause seizing, galling, and pitting. All of these issues can be easily resolved utilizing the proper procedure and the proper lubricants.

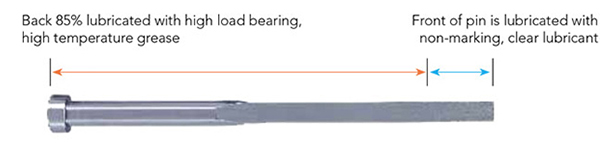

Lubricate the back 85% of the ejector pin with a high load bearing, high temperature grease, such as Slide Super Grease (No. 43911P). Then lubricate the remaining front 15% of the pin with a clear, non-marking lubricant, such as Slide non-aerosol Super Grease (No. 43900). Spray additional non-marking, clear lubricant in the sleeve of the pin. The pin can now be installed.

Periodically, you should apply additional lubrication to the front section of the pins. Set your ejector pin selection to manual and move the pins to the out or eject position . Spray the front of the pins with lubricant, then turn your machine back onto automatic and continue to make parts. This lubrication will need to be performed at least once a week. High-speed molds may require additional lubrication before every shift.

For additional lubrication behind the mold, such as on the ejector plate, use a high temperature aerosol lubricant with high load bearing, such as Slide Super Grease aerosol (No. 43911).

This procedure will help prevent a grease product from lubricating the front section of your pins, which can bleed out during a run. The grease bleed-out can result from destabilization caused by an improper mold cleaner, rust preventive, or high temperatures breaking down the grease. A dry film lubricant placed on the front section of your pins can minimize the chances of a bleed out. If a mold cleaner or rust preventive breaks down the pin lubrication, simply reapply as stated in the Additional Lubrication section. High temperatures will usually have no effect on dry film lubricants as their formulation makes them more stable at those temperatures.

Products discussed in this white paper:

Slide Super Grease non-aerosol 43900

Slide Super Grease aerosol 43911

GET EXPERT ADVICE ON INJECTION MOLD RELEASES, MOLD CLEANERS, RUST PREVENTIVES, EJECTOR PIN GREASE AND PURGING COMPOUNDS

Answers are just a click or call away!

A Slide Purging Expert will contact you before your samples are shipped to ensure you receive the best product and quantity for your specific purging needs.

Consent has been revoked on one or more services. In order to fully activate that change the page must be reloaded.