Mold Release, Cleaner & Rust Preventive White Papers

Cleaning molds is a key part of running a successful injection molding operation. It starts with choosing the right cleaner for your cleaning situation:

Offline – when the mold is cold (at room temperature) and on the bench, ready to be placed into storage, or

Online – when the mold is warm and still in the press, about to be used with a different resin for the next production run.

The determining factor for cleaning is mold temperature. Using a solvent designed for the wrong mold temperature may result in poor cleaning or excessive time to accomplish the job.

Offline solvents, for example, evaporate at a convenient rate, making them ideal for cleaning cold molds on the bench. But if those solvents are used on warm molds, they flashed off rapidly, preventing sufficient contact time for cleaning to be effective.

Online solvents work well at higher temperatures, making them perfect for cleaning warm molds. However, their aggressiveness and effectiveness diminishes at room temperature, making these solvents much less effective for cleaning cold molds on the bench.

Following is a description of the solvents available for offline vs. online mold cleaning to help you choose the one that works best for you.

With their very fast evaporation rate, offline cleaners such as Slide Mold Cleaner 4 readily dissolve resins, grease, oil, mold release and sometimes rust simply by flushing the mold with a heavy spray from top to bottom. While chlorinated hydrocarbons are the most effective, some non-chlorinated hydrocarbons and naphthas also work quite well.

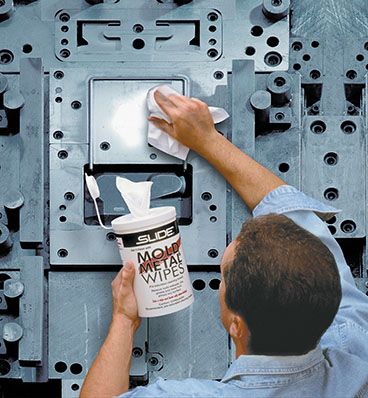

In some situations, a cloth saturated with cleaner may be required to scrub mold release and resin build-up off the mold. Pre-saturated mold cleaning wipes are now available to make this job easier. They come packaged in a canister similar to baby wipes. Among their advantages, wipes are:

Another option for offline cleaning is mold polish and cleaning compound – a combination of solvents and mild abrasives that has proven effective in removing contaminants from mold and die surfaces. It comes in a paste that must be applied and removed manually. An additional benefit is that it leaves a surface sheen or luster that serves as a natural lubricant and mold release, minimizing the need for other products when the mold goes back into production.

Online cleaners such as Slide On/Cycle Mold Cleaner are specially designed to remove mold release build up and light rusting from warm molds still in the press. Their slow evaporation rate allows chemicals to remain on the mold surface for a longer period of time, maximizing cleaning effectiveness.

One of the toughest cleaning jobs is removing acetals such as Delrin® and Celcon® or fire retardant materials that adhere to warm molds. These build-ups can cause mold "plate out," impacting quality. This gas build-up must be chemically removed from the mold surface in order to minimize potential part deformation. Resin removers are designed to break down this residue and help remove unwanted resin from the mold surface.

Using effective cleaning solutions from Slide Products will help you increase manufacturing efficiency and decrease overall costs. The best way to know which products work best is to try them out. Trial samples of all products are available at SlideProducts.com.

Not sure where to start? Our extensive network of local distributors can help you with product selection. You can also contact us or call Slide at 1-800-323-6433.

GET EXPERT ADVICE ON INJECTION MOLD RELEASES, MOLD CLEANERS, RUST PREVENTIVES, EJECTOR PIN GREASE AND PURGING COMPOUNDS

Answers are just a click or call away!