|

||

| ||

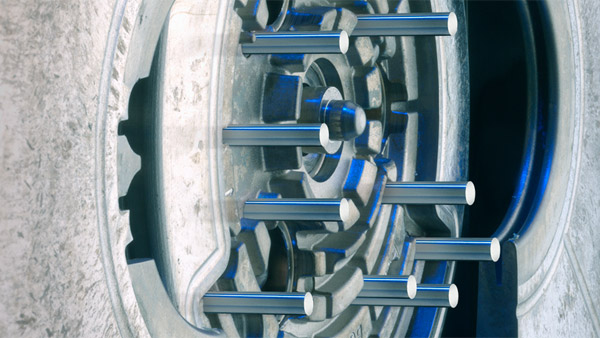

How the Proper Lubrication Keeps Ejector Pins SlidingPrevent bleed out onto the tool surface. Minimize the chance of defective plastic parts. Prevent galling, seizing and pitting by avoiding deterioration of the grease. Apply lubricant the wrong way, or use the wrong lubricant any way, and you pay a heavy price...bleed out...defective parts....and tool damage. Preparation, Preparation, Preparation Lubricate the back 85% of the ejector pin with a non-aerosol grease product that has high load bearing properties, and that will not separate and fall out. The grease should also be clean and clear and not yellow. If you have a food application or do medical molding, use an NSF certified grease. Next, lubricate the remaining front of the pin with a clear lubricant that is paintable and will not mark parts. Also spray the lubricant into the sleeve of the pin area for additional lubrication. Now you are now ready to install the pin. Monitor and maintain Apply the same lubricant you used on the front 15% of the pin before a production run to insure proper lubrication of the pins. To start, set your ejector pin selection to manual and move the pins to the out, or eject, mode. Spray the front of the pins and turn your machine back to auto and continue to make parts. This will not affect the mold surface because you are using a fully paintable product. Apply lubricant at least once a week. However, high-speed molds may require lubrication before every shift. Different molds and applications will require different procedures for additional lubrication. For additional lubrication behind the mold, such as on the ejector plate, use an aerosol grease with the same high lead bearing properties as the grease used on the back 85% of the pins. Reap the benefits Following these steps every time has several benefits. This procedure prevents grease from migrating to the front section of your pins. Mold cleaner, rust preventive and high temperatures can then cause the grease to break down and bleed out onto parts. A dry film lubricant placed on the front section of your pins minimizes the chance of bleed out. If a mold cleaner or rust preventive breaks down the pin lubrication, simply reapply lubricant as outlined above. High temperatures will usually have no affect on dry film lubricants because of their temperature stability. Test product before putting it into production Taking the simple steps outlined above and using an effective pin lubricant like those offered by Slide will help to reduce rejected parts and prolong tool life. Which lubricants does Slide recommend. Try our online product selection tool, or contact your local Slide Products representative. Learn more about mold releases, cleaners and rust preventives | ||