Mold Release, Cleaner & Rust Preventive White Papers

Just so you know, action heroes really can’t make a torch using any aerosol can and a lighter. That’s just Hollywood.

Nothing in the formulation changed. It’s the same aerosol you’ve been using for years. But now the government has found a different way to define “flammability.”

Previously, an aerosol formulation was tested using the Aerosol Flame Projection Test. This test measured the actual flammability levels for an aerosol formulation, and it provided a true assessment of the hazards and needed warnings.

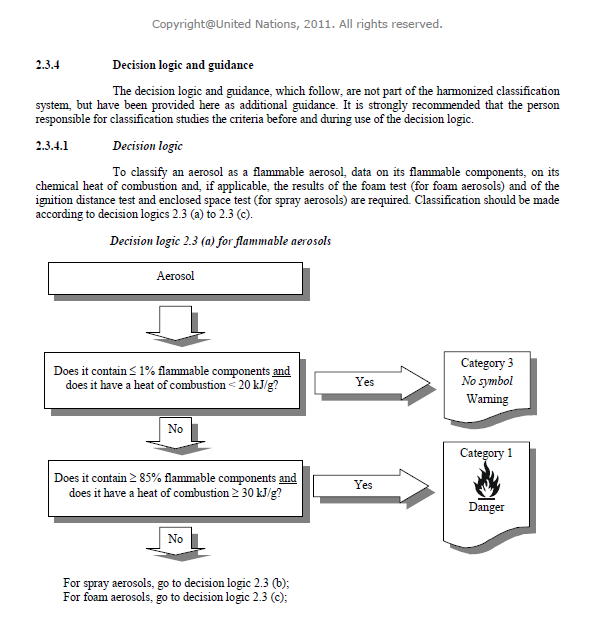

Now, the new GHS regulations have abandoned this testing methodology and replaced it with a mathematical calculation that has very little to do with the actual flammability levels of a particular aerosol product. Every maker of aerosols has to follow the “new math.”

Slide has used the new math for all of our products and the results have every Slide aerosol formulation, except one, now requiring a flammability warning on the Safety Data Sheet and product label. This is will be same for all the other aerosol makers, too.

Using the new math, to create a nonflammable aerosol is nearly impossible without using an extremely expensive formulation. So the end result is that all aerosol makers rolling out new GHS-compliant product labels will show products that were previously labeled as nonflammable will now be required to carry the flammable warnings.

So, if you are using an aerosol formulation that was chosen because it was designated as nonflammable, and now is listed as flammable, contact your supplier and determine if the formulation has changed, or if this is a result of the new math.

Slide is well versed in the new GHS requirements and will gladly help you navigate the new label designations.

GET EXPERT ADVICE ON INJECTION MOLD RELEASES, MOLD CLEANERS, RUST PREVENTIVES, EJECTOR PIN GREASE AND PURGING COMPOUNDS